|

Can Cannon? Can! First, the bad news: I left my camera at my in-law's on Friday night, so no pictures of Friday's activity. On to Saturday.

After a delicious and nutritious breakfast at the Main Street Cafe in Toledo, I found Micha and Tawna launching their kayaks at the Boathouse. They were heading down for a lunch at Newport. Have a blast, guys.

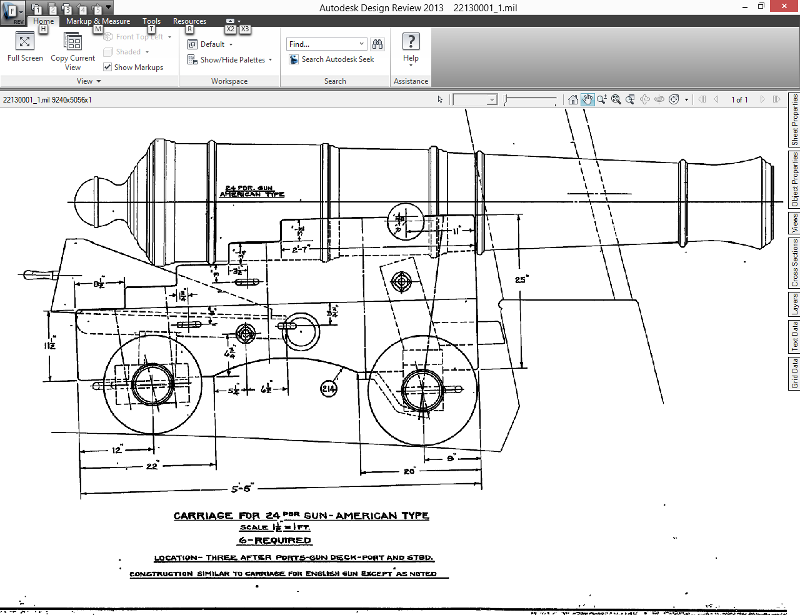

I am basing the design of the cannon's carriage on the information found on this web page combined with accurate drawings from the armament of the USS Constitution. Our cannon is shorter and fatter(proportionally) than the 24 pounders used by the British and American navies, but it's close enough. In addition to shrinking the design some 89%, I made a few other little tweaks to fit constraints.

The wheels are from 2 layers of 1/2" mahogany. The layers are rotated 90° so the wheel won't crack in one direction. The forward wheels are 3" in diameter, the rear ones are 2 1/2" in dia - fitting the holesaws I have.

In the design, the axle is stationary - the wheel rolls around it. The originals had an iron bushing that helped prevent the wheel from cracking under the strain of hosting the cannon (the cannons were 5700bs and threw a 24lbs ball over a miles - lots of strain.) Since the trunnions are 1" in diameter, I decided the axles should be 1" dia, too, minimizing the parts I need to fab. Turns out, 1" copper pipe is almost exactly 1" inside diameter., and I had a 1 1/8" dia holesaw, so things worked out perfectly (and cheaply - except copper pipe is $5.49 a foot!)

I needed to make a jig for slicing the pipe - a mechanic's square, a couple clamps, and a piece of scrap worked nicely. The bushings for the wheel would be 1" thick, the straps for the trunnions would be 5/8".

These will become the straps for the trunnions - theses straps will hold the cannon to the carriage - well, these straps, gravity, and inertia, I suppose.

This is what I am aiming for - a carriage roughly based on the ones from the USS Constitution, made from mahogany with w\mahogany wheels with copper bushings on hardwood axles. It will elevate and depress ~15°/10°, just like it's supposed to. Should be fun.

My final step for the week was to epoxy the bushings into the wheels. I made them a little proud so when I sand them off, they'll be perfectly flush with the wheel. Since the axles were white wood, I stained them (they are standing in the background.)

During he day, I looked up and saw a person in a suit walking by the Boathouse. Since we don't get many people in suits down a the docks, I went out and introduced myself. It turns out Ethan had seen the Teak Ladies floating at the docks and wanted to take a peek.

Back at the Boathouse, Ethan and I ran into Barry and Betty. I love this picture because Barry loves everything about boats and the Boathouse and poor, long suffering, Betty indulges him. They live in St. George, Utah, and had taken a little trip to see what they could see.

They, like everyone who sees one, fell in love with the Teak Ladies. Beautiful boats call to the soul. That's all for this week. See you on the 16th.

|