I am getting tired of building square boats, so I wanted to try something new. While lapstrake and clinker boats have a certain appeal, I'm not interested in buying the quality materials a person need to build such a boat. Plus, they take a while to make and require lots of skill. I do my work at the other end of the spectrum: Quick, cheap, and simple.

Skin on Frame boats (SOF) look to be just what the doctor ordered. You make a frame and skin it with Dacron or polyester cloth, heating the cloth with an ordinary iron, shrinking it to the frame. Because the stick you use to make the frame are thin and bendy, you can get some really nice shapes without the need to plane and bevel. The cloth is fairly cheap - Dacron runs ~$4 a yard and polyester is ~$6 a yard.

The only drawback is there is a lot of preparation. That's what this essay is about.

Step 1: The Pattern

Chuckanut 15 plans are free for the asking, and when you ask, Dave Gentry will email you instructions and a full-sized layout of the frames in PDF format. I took it to Kinkos and after only 6 tries (and 3 people helping me) we were able to get the 2'x6' printout. It was frustrating, but it only cost $8 (75 cents per square foot)

I plan on making several Chuckanut 15s, so I wanted to make templates of the frames so I could just trace the template and start cutting. Carbon paper is the answer here (Office Depot, $4 for 25 sheets, I used - and reused - 5 sheets.)

Since there was no cutting or sawdust, I was doing this in my living room While Schnauzers are loving, loyal, brave, and trustworthy, they are not helpful. beBop simply could not understand that the pattern was not for standing on.

Ta Da! One frame down, 5 more to go.

The plans call for the frames to be cut from a 2x6 sheet of 1/2" ply. I didn't have any 1/2", but I did have a full sheet of 5mm Luaun. A little TiteBond and a lotta pressure, and I had a 2x6 sheet of 10mm ply, which is gonna have to be good enough.

I needed to make a run to Lowes for more supplies. I needed enough straight-grained wood to get (2) 16ft 1x2's and (3) 16ft 1x1s - and I needed a sheet of plywood to make a strongback. $13 for the 2x10 (barely enough knotless wood for the requirements) and $12 for the 19/32 CDX for the hollow strongback. Sadly, I rushed the strongback construction, so it is a tad out of true.

Pfft, big deal. I'm not gonna let that stop me.

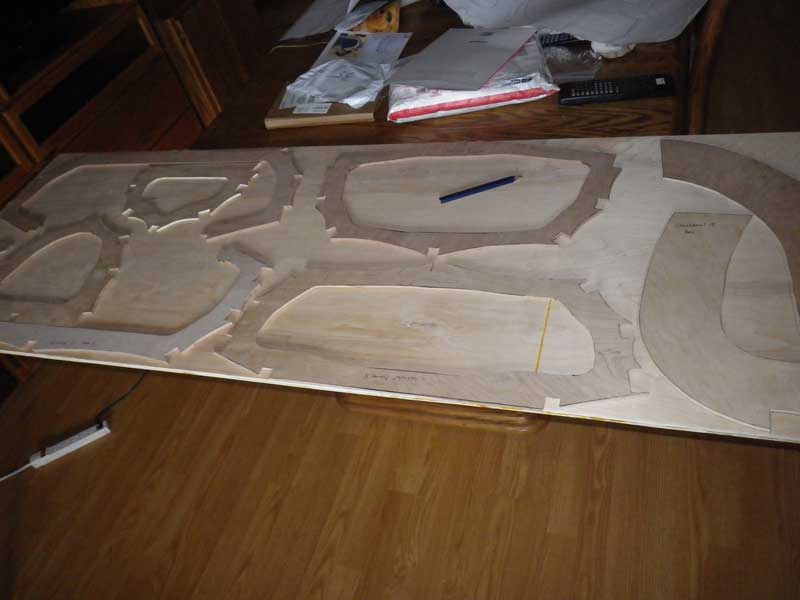

The lamination had cured so I transferred the templates of the frames and got to cutting.

The instructions say "Clamp the frames to the strongback . . . but wait a minute. How is this gonna work? This doesn't look right at all.

That's because it wasn't I had the frames upside down.

Rightside up and leveled I started trying to see how the frames fit the gunnels and stringers. I'm not the best template maker, and I'm not the best woodcutter, so things weren't fitting together very well at all. I started thinking the plans were wrong, so I reread them. Dave CLEARLY states you should put a permanent bend in the gunnels or suffer fighting the wood.

Fine, pre-bend the gunnels it is. This is my bending jig - very scientific. I wrap the boards in towels (shop towels, not towels from the bathroom,) suspend the boards between two sawhorses, and soak the towels with a hose. Just for fun, I tossed some weight in the middle. I'll let this set overnight and see how it looks in the morning,

A wise man would use hot water.

I once saw a picture of an Inuit making a kayak in the traditional way. He had a stick of driftwood in his mouth, using the heat and moisture from his breath to soften the wood while he used his jaws as a clamp and bent the ends of the stick down with his arms. Not me: I have bad teeth.

The next step is to return to the strongback and dry-fit all the parts together. Once things seem to be fitting, it'll be time to last the stringers to the frames and make the skeleton to which I will attach the skin.

I have (4) Skin on Frame boats I'll be experimenting with:

- Dave Gentry's Chuckanut 15 - a two person kayak

- Dave Gentry's Ruth - an 18' rowboat that will be configured for two rowers

- Geodesic Ariolite's Snoeshow 16 - a 16ft canoe

- Geodesic Ariolite's Classic 14 - a 14ft rowing wherry that can be rigged for sail

Tom Yost has an excellent site for making folding kayaks and other skin-on-frame boats: Yostwerks